completed

Wiesbaden, Germany

| Project start: | 09/2002 |

| Completion: |

12/2007 |

| Project type: | Renovation |

| Venue type: |

Drama theatre, Opera house, Ballet theatre |

| Seats: |

Main theatre: 1041 seats |

| Our services: |

Schematic design, design development, construction design, tender documents and construction supervision for stage machinery, electroacoustic, video system and paging |

| Contact: |

Client: Hessian building management authority, regional office West |

Renewal of electroacoustic-, video- and stage management systems including:

- Complete stage management system with paging and emergency call systems for three buildings, total 80 P.A. circuits.

- CCTV and video system with satellite connection

- Three stages are connected via MADI

- Complete renewal of network distributions controlled via SPS

- The system includes a server with 4TB hard-disc capacity with backup-function. Audio-network designed as Gigabit Ethernet system.

- Complete low resistance loudspeaker system for the studio stage

- Renewal of the sound control room in the Main theatre, including 1 digital mixing panel, digital cross-bar and amplifying stations

- Digital mixing panel, digital cross-bar and amplifying station for the Small theatre

- Digital cross-bars and amplifying stations

- Complete low resistance loudspeaker system in the Small theatre, with 100V-equipment

- Production studio “Studio 1” with digital mixing panel, digital cross-bar, MADI-Interface to all 3 stages, audio workstation with 64-channel-recording with MADI-Interface and various effect- and playback equipment

Main Theatre:

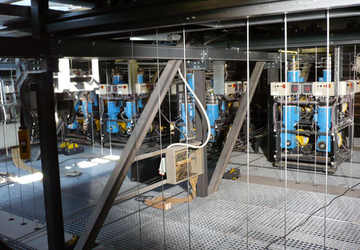

Renewal of stage machinery including:

- Renewal of the steel structure including grid level, level of pulleys, machine level

- 40 powered fly bars, payload: 650kg, v = 0 - 1,8 m/s

- 46 point hoists with movable wire rope output, payload: 350kg, v = 0 - 1,8 m/s

- 4 lateral fly bars, payload: 650kg, v = 0 - 1,8 m/s

- 3 proscenium fly bars, payload: 650kg, v = 0 - 1,8 m/s

- 1 house curtain, Greek (traveller) and German (guillotine) opening style

- 4 powered fly bars in paint shop, payload: 350kg, v = 0 - 0,3 m/s

- 2 powered fly bars in decoration storage, payload: 350kg, v = 0 - 0,3 m/s

- 2 powered fly bars in storage, payload: 350kg, v = 0 - 0,3 m/s

- Movable prompter box

- Trap doors in the stage floor

- Various refitting works on stage and on working galleries

- Outfitting the whole understage machinery with shear-edge protection

- Complete electric and electronic layout of the centralized control system including main and secondary control consoles for all drives of the overstage and understage machinery.

Small Theatre:

Renewal of stage machinery including:

- Renewal of the steel structure including grid level and level of pulleys

- Maintenance catwalk above apron stage

- 34 point hoists aligned in 9 rows, designed with two suspended wire ropes and lifting block, payload: 250kg, v = 0 - 1,2 m/s

- 1 powered fly bars, payload: 350kg, v = 0 - 1,2 m/s

- 6 apron stage powered fly bars, payload: 350kg, v = 0 - 0,3 m/s

- 5 backstage powered fly bars, payload: 350kg, v = 0 - 0,3 m/s

- Smoke exhaust system, driving device, v = 0,1 m/s

- Complete electric and electronic layout of the centralized control system including main and secondary control consoles for all drives of the overstage and understage machinery.

Phase 1

Design

Phase 2

Construction

completed

Phase 3

Handover

completed

This site uses technical cookies to provide you with a great user experience. By using it, you accept our use of cookies.